Our Expertise

BMEA has extensive expertise in all areas of bulk materials handling and prides itself on delivering customised programs of work tailored to meet your exact needs.

If your specific need is not listed, contact us to discuss further.

BULK MATERIAL FLOW PROPERTIES

- Measurement techniques for wet and dry bulk solids

- Wall yield loci and wall friction angle determination

- Instantaneous and time yield loci, flow function and effective angle of friction

- Particle/solids density

- Bulk density (e.g. loose-poured, tapped, vibrated)

- Angle of repose (drained/poured)

- Particle sizing (mechanical sieving/laser)

- Moisture content and saturated moisture content determination

- Determination of maximum strength moisture content

- Powder aeration, deaeration and settling

- Transportable moisture limit (TML) determination

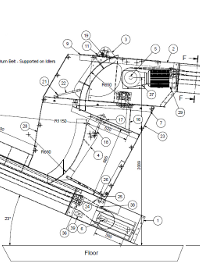

BIN AND HOPPER DESIGN

- Hopper half angle and critical outlet dimensions

- Plane flow and axisymmetric flow

- Mass flow and funnel flow

- Arching and critical rathole dimensions

- Flowrate prediction

- Feeder loads

- Predicting the loads/pressures exerted on hopper walls

- Design and analysis of bin dischargers and feeders

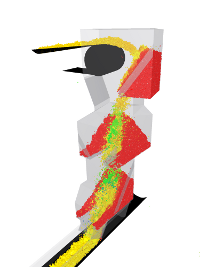

SIMULATION MODELLING

- Discrete element modelling (DEM)

- Computational fluid dynamics (CFD)

- Coupled DEM-CFD simulations of solid/gas interactions

- Material testing for DEM and CFD calibration purposes

- Determination of material model parameters

- Simulation Modelling of industrial applications

- Third-party verification of design solutions

DUST CONTROL

- Dustiness testing (Australian and International standard testers)

- Dust extinction moisture determination

- Dust lift-off determination

- Design and analysis of dust control systems

- Modelling of dust suppression systems (e.g. dry fogging)

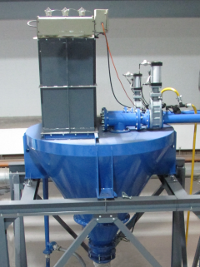

PNEUMATIC CONVEYING

- Fluidised dense-phase

- Dilute-phase flow of powders and granules

- Low-velocity slug-flow

- Powder fluidisation, deaeration and settling

- Dust-fume control systems

- Dust explosion hazards and control measures

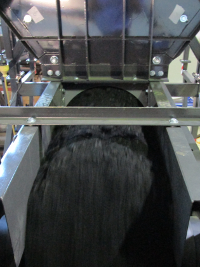

BELT CONVEYING

- Gravity chute and conveyor transfers

- Maximum belt inclination angles

- Chute inclination angles

- Determination of minimum chute slopes

TROUBLESHOOTING AND DESIGN AUDITS

- Troubleshooting of plant and process problems

- Analysis, evaluation and/or optimisation of existing systems

- Feasibility studies

- Technical and/or safety audits of handling plants and processes involving bulk solids

- Independent review of contracts, bids and specs for new equipment, processes and/or plants

- R&D of new industrial technologies relating to bulk solids handling and dust-fume control

- Concept design parameters, hardware and operating requirements and equipment layout